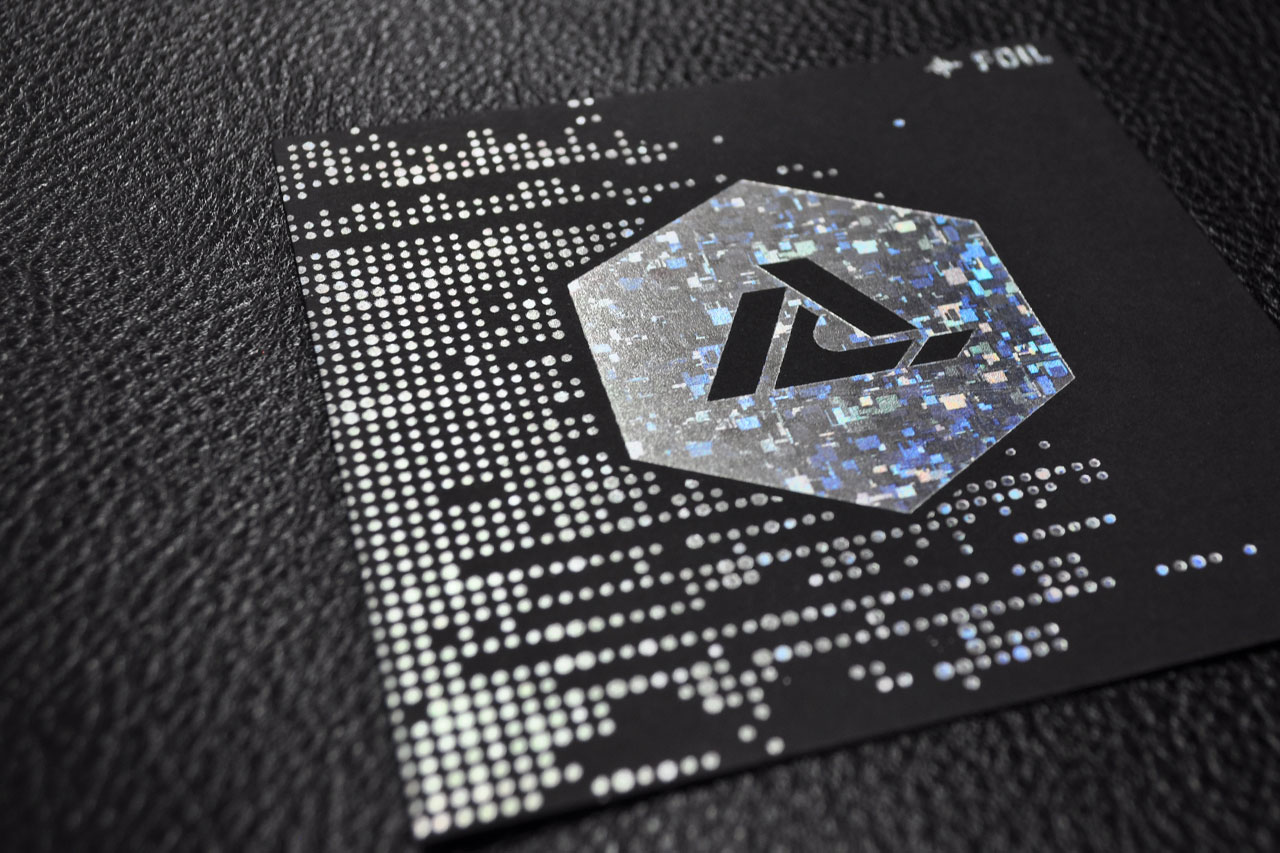

Hot Foil Stamping

Discover our stamping solutions

O processo de estampagem permite criar um fator de diferenciação e obter um aspeto mais cuidado e exclusivo nos seus produtos.

Make the difference

Types of finishing:

- Hot Foil Stamping

- Embossing

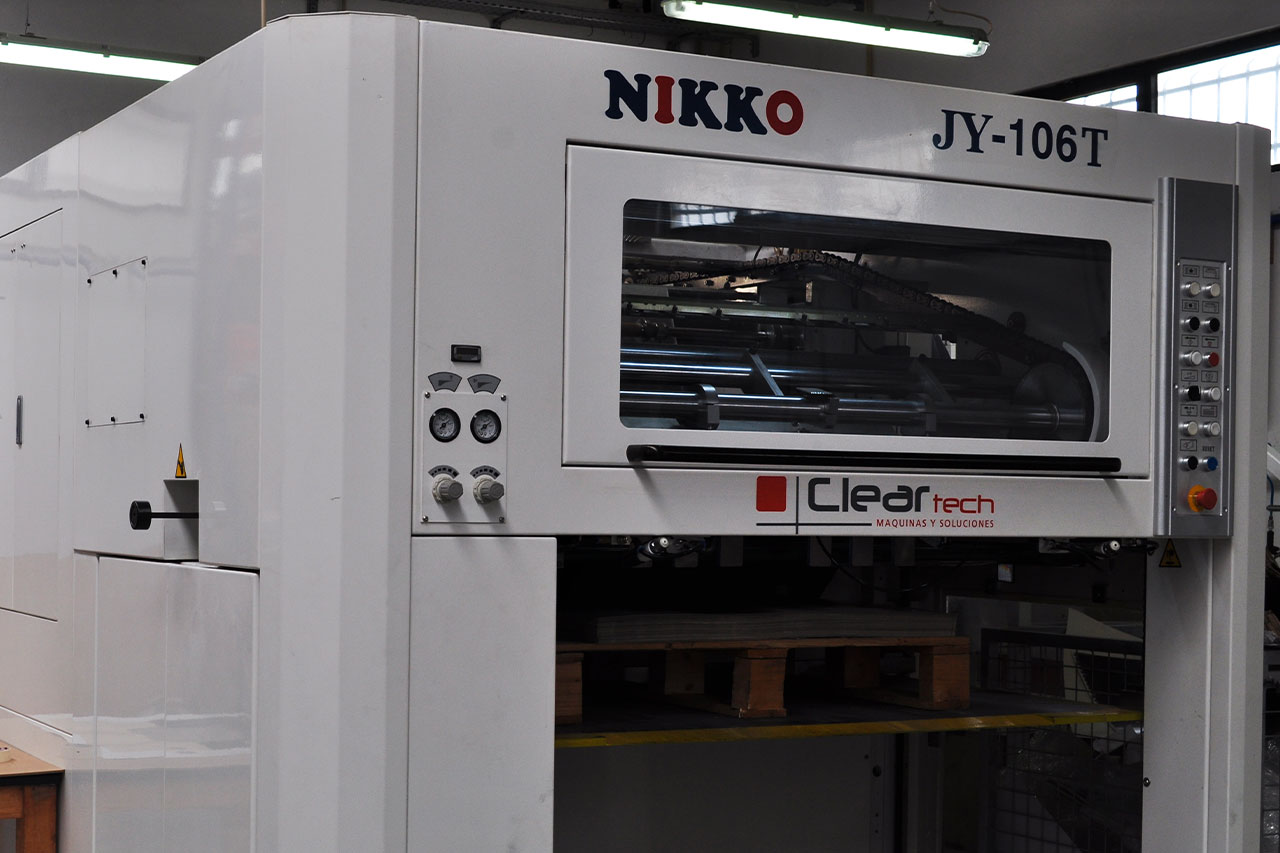

At CORTARTE, we have a wide range of hot foil stamping solutions with and without embossing. We use this technique on various substrates, such as paper, cardboard, PVC and plakene, and we have a variety of foils for personalising your products.

Hot Foil Stamping

Hot stamping is a printing technique that applies a metallic or pigmented foil to the surface of the paper using heat and pressure. This process creates a glossy finish, perfect for highlighting graphic elements.

This process offers unrivalled visual elegance thanks to the refined finish. It can also be applied to different types of substrates.

Embossing

Relief can be categorised into embossing and debossing, two techniques that create raised and lowered impressions, respectively, on the surface of the paper. This method gives a distinctive aesthetic to elements that need to be emphasised.

This technique provides tactile interactivity and visually highlights logos and titles, adding a unique and attractive sophistication to printed materials.

Learn about our production process

The stamping process makes it possible to create a differentiating factor and achieve a more exclusive and premium look.

Our goal? Provide our customers with excellent products!

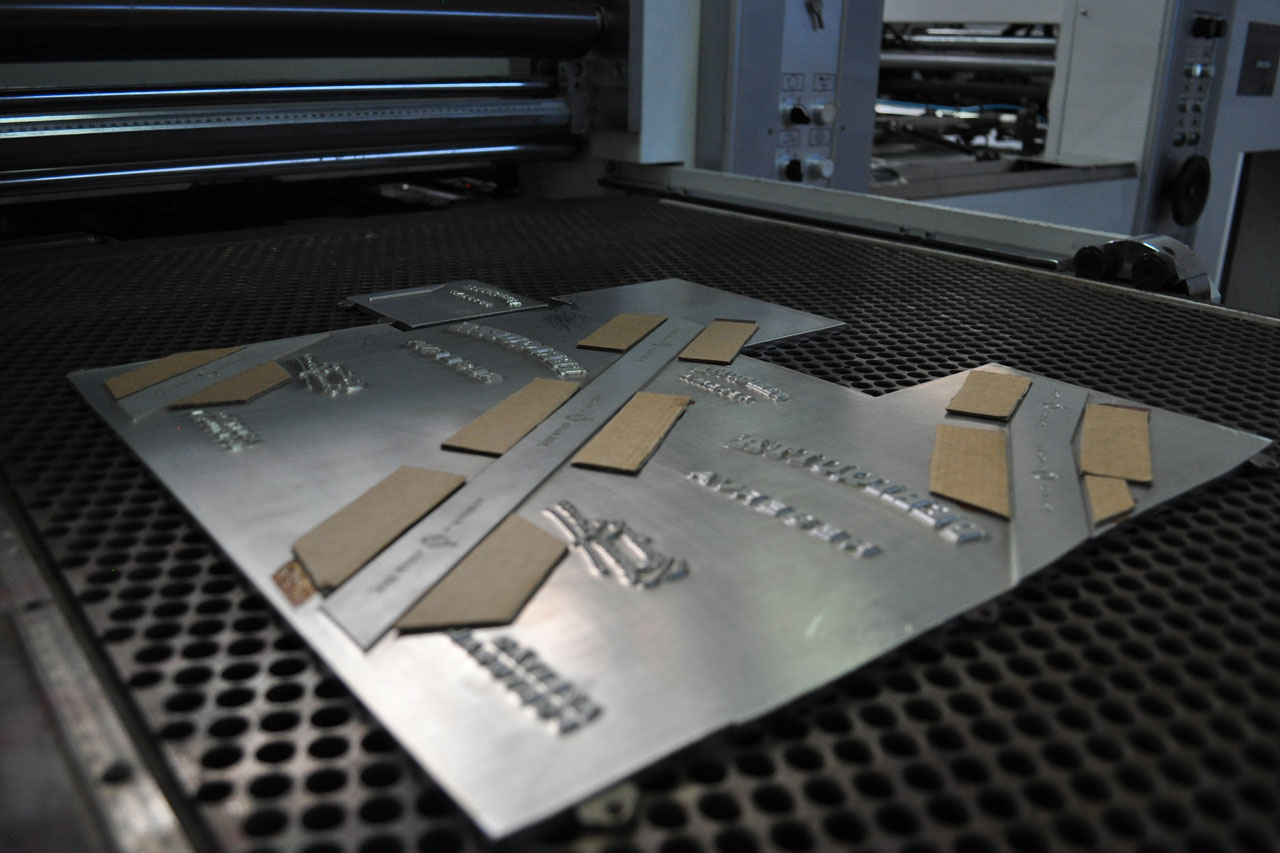

The process starts with a magnesium engraving plate that can be provided by the customer or produced by Cortarte. In both cases, a photolith with the actual size of the stamping is printed to make adjustments to the print.

The engraving is assembled in compliance with the job requirements, and a test is carried out before starting the stamping process for quality inspection.

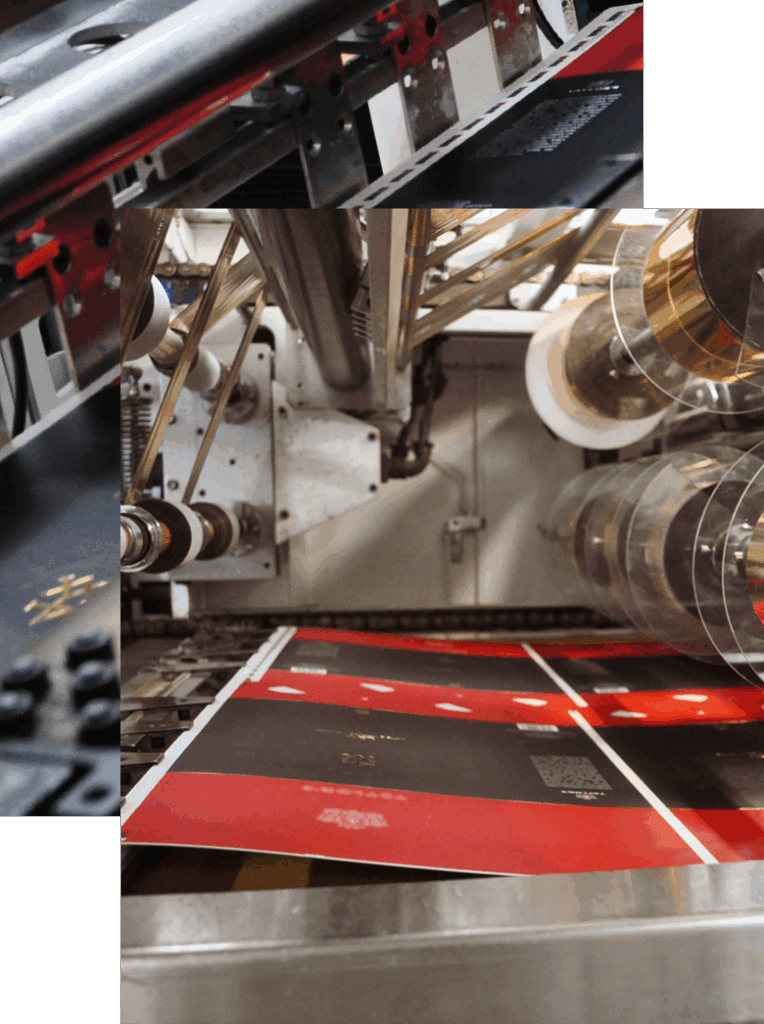

During this stage of the process a transfer film is used. This film is placed between the substrate (paper, pvc and plakene) and the engraving plate that has the design of what we want to print. The combination of pressure and activation of adhesive causes the sheet to stick to the substrate.

The product is ready with differentiated and unique finishes!

Would you like to request a quote?

Contact us