Flexography

Flexographic cliché specialists

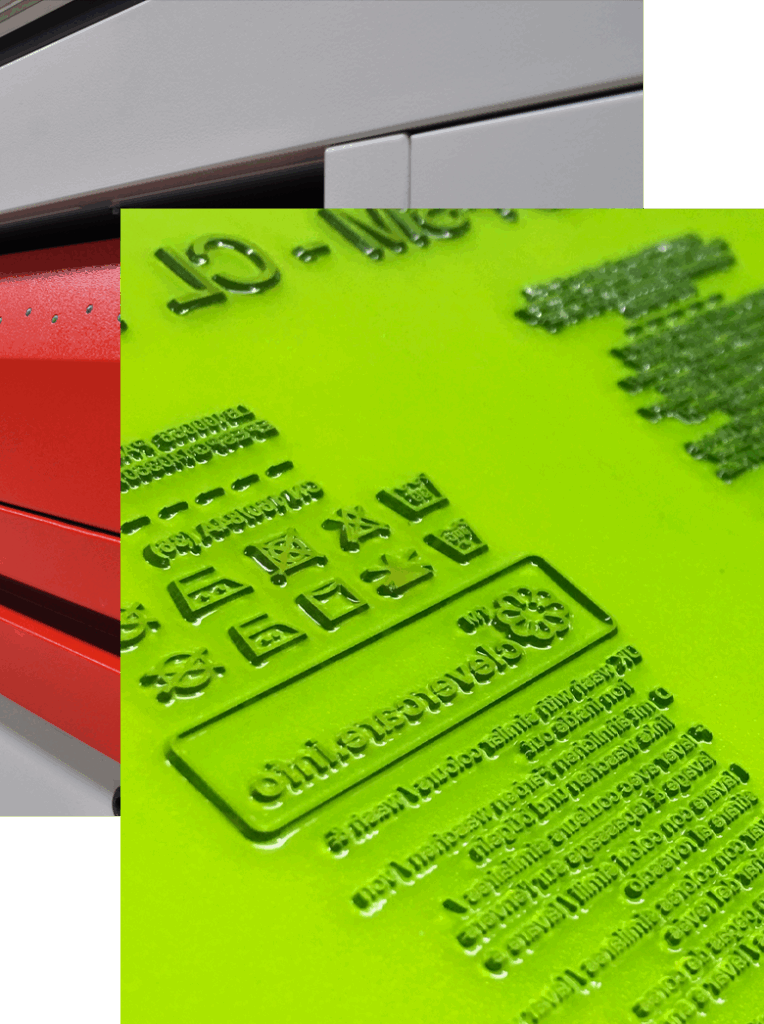

We produce flexographic clichés in various thicknesses, ideal for different materials and applications. We guarantee high definition and durability in every print.

High definition flexographic plates

- - Corrugated Card

- - Flexible Packaging

- Hang Tags

- - Automatic and Manual stamps

At CORTARTE, we manufacture flexographic clichés digitally. We provide multiple options for engraving flexographic plates, with various types of webs, in the various polymer thicknesses available on the market.

Flexographic cliché thicknesses

The choice of cliché thickness directly influences print quality, depending on the material and the specific application.

Hang Tags: For label printing, it is recommended to use clichés with thinner thicknesses, such as 1.14 mm and 1.70 mm. These thicknesses guarantee fine detail and high resolution, and are ideal for labels containing small texts and detailed graphics.

Bags: Relativamente aos sacos – sejam eles de plástico ou papel –, geralmente optamos por espessuras intermédias. Clichés com 2,54 mm e 2,84 mm oferecem um bom equilíbrio entre durabilidade e flexibilidade, permitindo, assim, impressões claras e precisas em superfícies mais texturizadas ou flexíveis.

Card: Para materiais mais espessos e rígidos, como o cartão, os clichés com uma maior espessura oferecem mais resistência e durabilidade. Por isso, recomendamos espessuras de 3,94 mm, 5 mm ou 6 mm para superfícies robustas.

Learn about our production process

We constantly invest in technology to guarantee the highest quality in our products.

Our goal? Help our customers to achieve fantastic results on their prints!

The design or request is conceived by designers according to the client's requirements, taking into account all the necessary technical specifications. The approved model is color proofed for analysis of the final product. The job is sent to production notifying the customer.

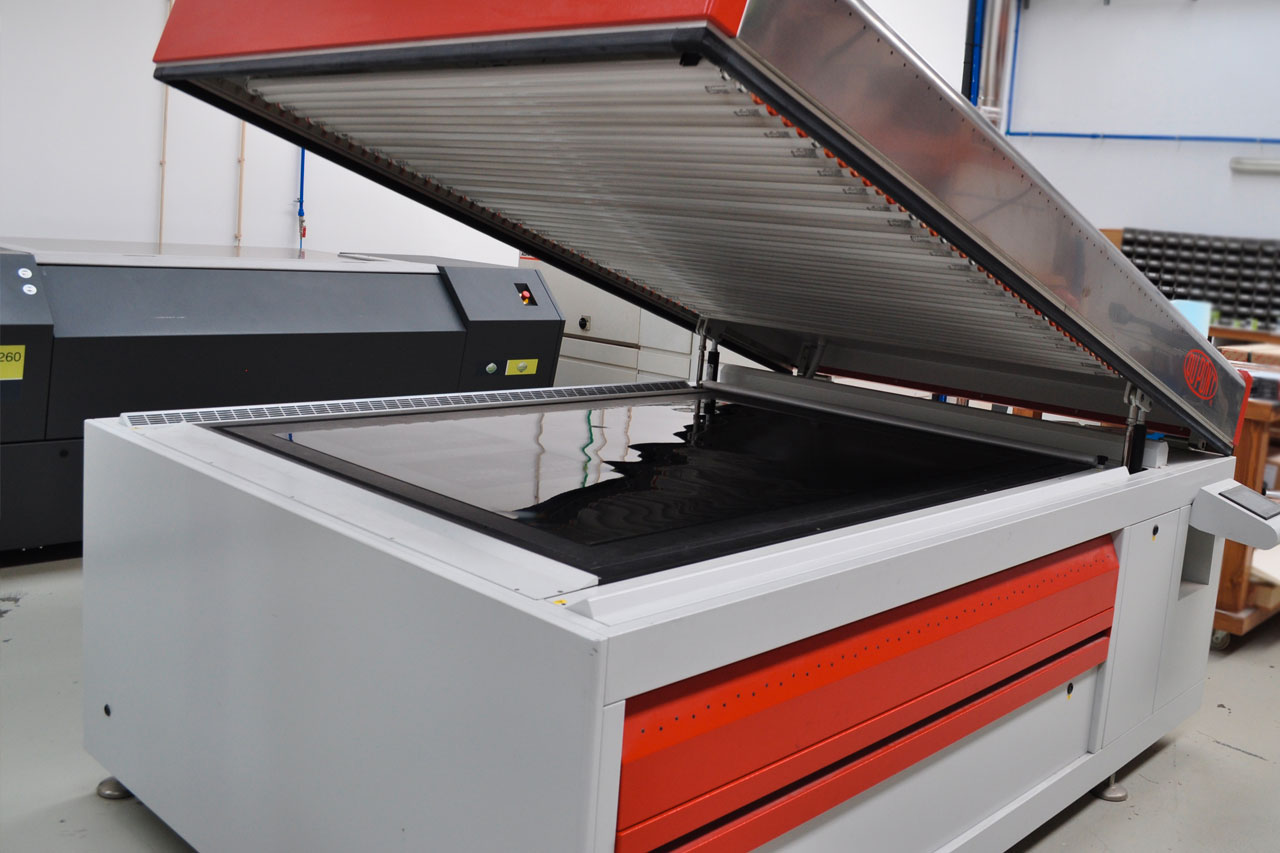

Exposure to UV light through the substrate film on the back of the plate in order to give depth to the final engraving.

Laser engraving of the image onto the plate is performed by contacting the emulsion side of the negative film on the plate surface.

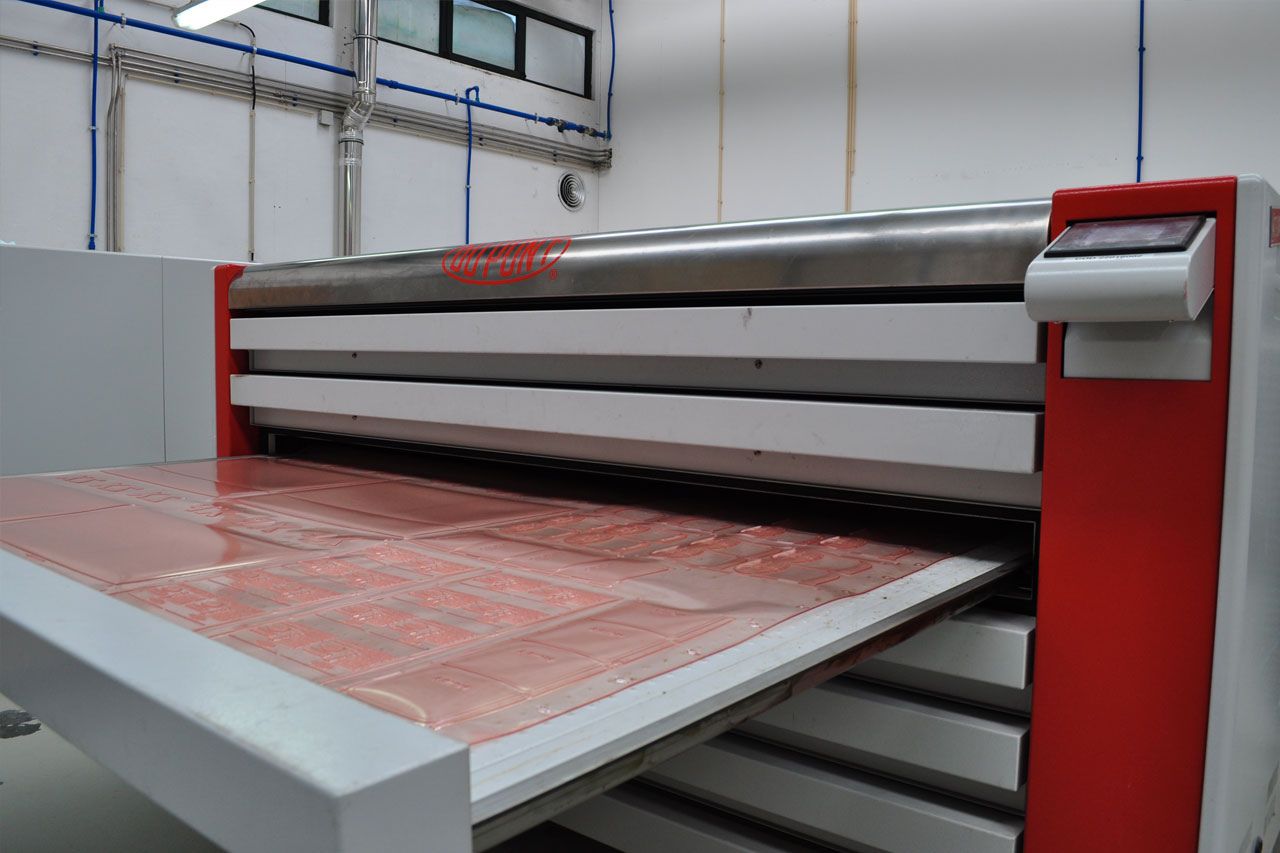

In this part of the process, the polymer is removed which, at a later stage, gives rise to the relief of the flexography plate.

The flexography plate now undergoes a drying process in the oven machine, lasting approximately two hours.

Finally, the flexography plate is exposed to UV light and germicide for a final finish. The flexography plate is ready to be shipped to the customer.

Would you like to request a quote?

Contact us