Die Cutting

Customised cutting solutions

Desenvolvemos cortantes adaptados às necessidades específicas de cada setor, garantindo precisão, eficiência e qualidade em cada projeto.

Innovative Quality Die Cutters

At CORTARTE we manufacture cutters for the printing, automotive and leather goods industries. Our cutters are precise, durable and adaptable to the specific requirements of the sector.

With software and machines constantly being updated, we are constantly on the lookout for creative and innovative solutions to apply to our cutters.

Cutting dies for the graphic arts industry

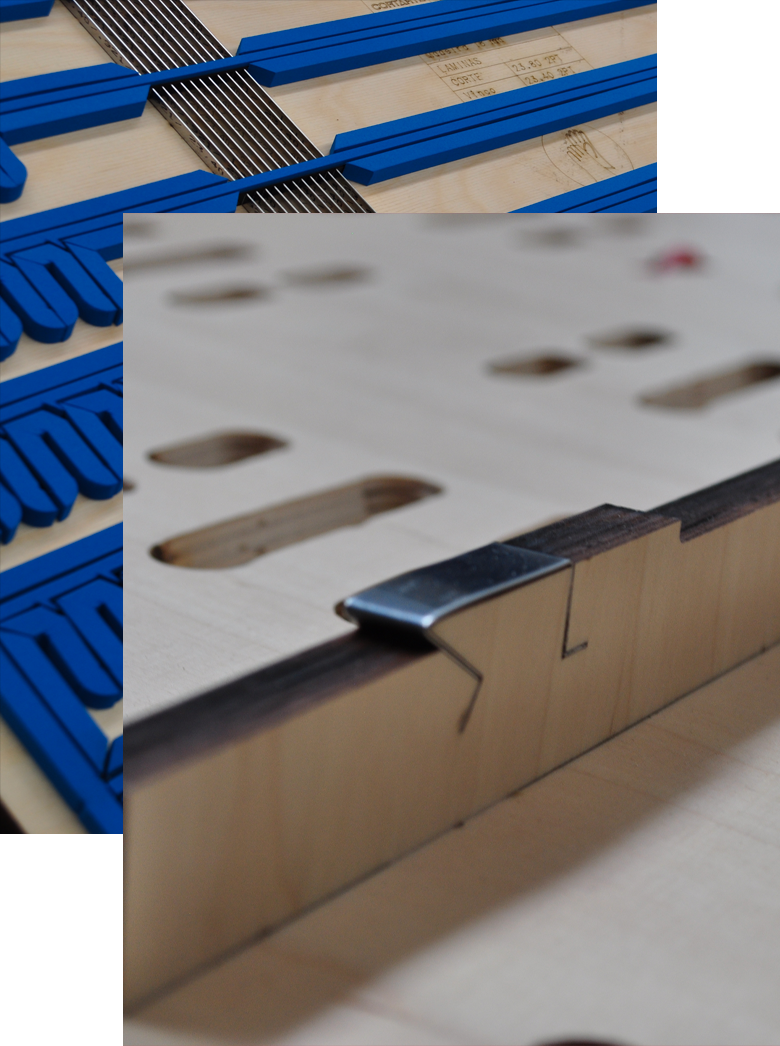

- Die Cutting

- Stripping unit

- Counterparts: creasing channel, pertinax, and milled plate

- Add-ons: braille, engravings, nylon molds for formers (food-grade certified)

- Prototypes

We offer high-precision flat cutting dies for flatbed die-cutting and creasing machines, ideal for working with paperboard and cardboard. Developed with advanced technology, our dies ensure clean cuts, accurate creases, and excellent durability, optimizing production and reducing setup time. They are recommended for packaging, displays, and other graphic products that demand quality and efficiency.

Cutting dies for the leather goods industry

- Wood-based stripping dies

- Cutting dies for filleting

- Checking fixtures

We manufacture high-precision cutting dies for natural and synthetic leather, used in the leather goods industry. Ideal for producing wallets, handbags, belts, and footwear. They deliver exact cuts, even in fine details, meeting the quality and care standards required by the leather and fashion accessories industry. Made from highly durable materials, they ensure superior performance even in demanding and detailed production environments.

Cortantes para o Setor Automóvel

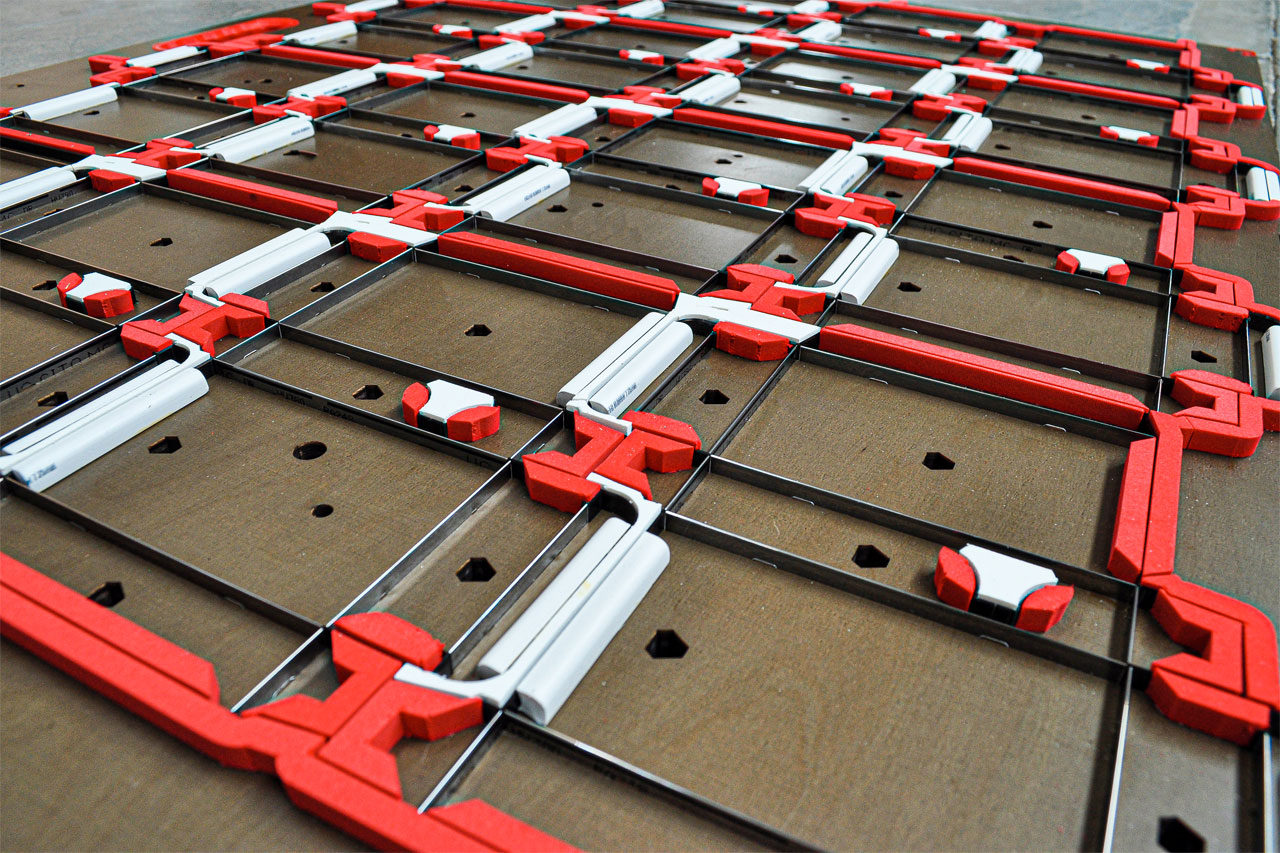

- Die Cutting

- Positioning and checking fixtures

- Stripping unit

We develop high-precision cutting dies for technical foam used in the automotive industry. Ideal for interiors, acoustic insulation, and technical components, our dies ensure clean cuts without deformation and perfect fit on assembly lines. Manufactured with highly resistant materials, they are compatible with various types of foam and deliver productivity and consistency in high-volume production.

Learn about our production process

We have an experienced and highly qualified technical team dedicated to guaranteeing quality and precision in every project.

Our commitment is clear: to create cutting edges of excellence that meet the requirements of each customer.

Os nossos desenhadores especificam o produto às necessidades concretas de cada cliente e dos seus equipamentos.

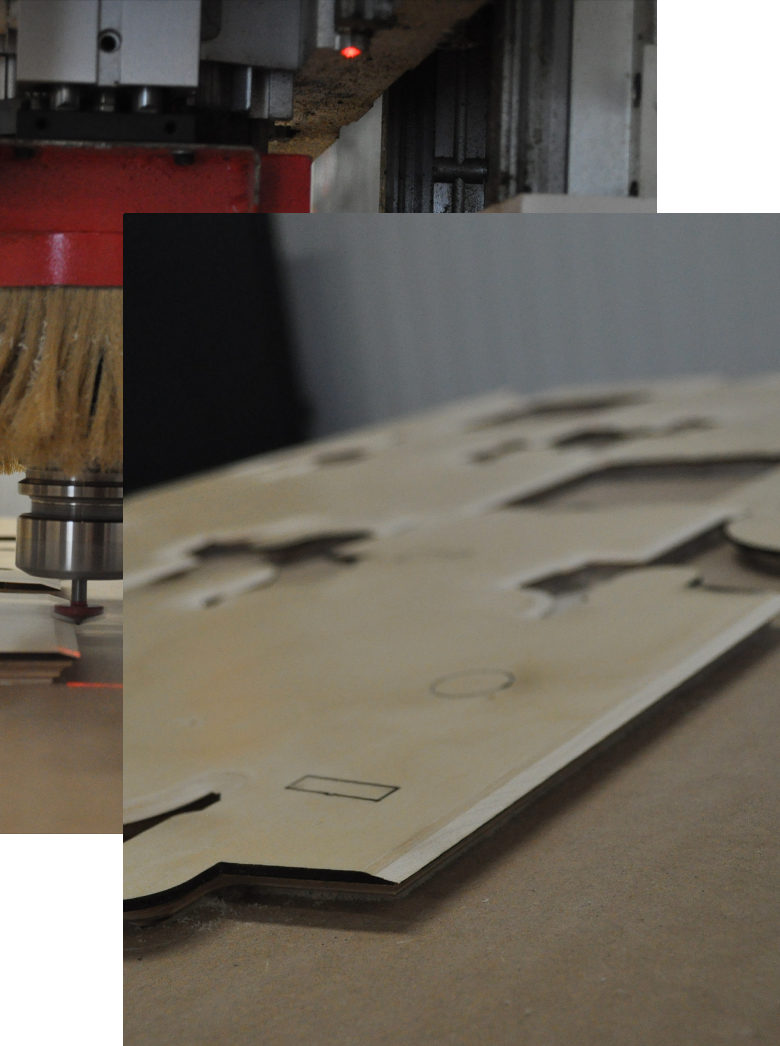

A máquina de corte a laser recebe a informação e o trabalho é realizado com a mais elevada precisão.

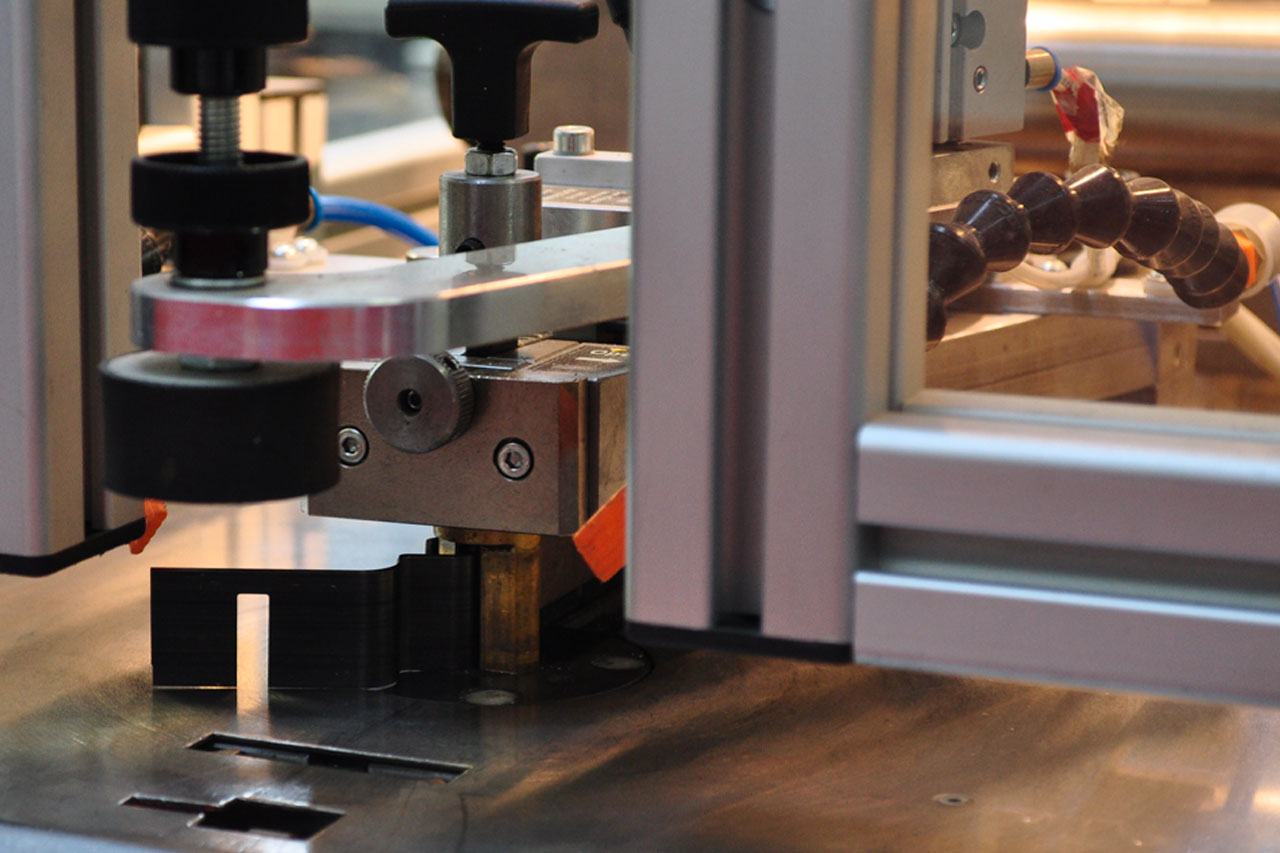

É efetuado o corte e a dobragem de lâminas, cuja escolha depende do trabalho requerido. Cada máquina recebe informação e procede a operação com máxima precisão.

A montagem das lâminas é feita por um operador especializado que procede os ajustes necessários para a obtenção de um cortante exemplar.

Após o trabalho de montagem das lâminas e de uma inspeção final de qualidade, o cortante encontra-se finalizado.

Once finished, the cutter is placed in storage for dispatch.

Would you like to request a quote?

Contact us